The lifeblood of air conditioning and refrigeration is keeping the gas inside the pipes at pressure. However, gas is almost impossible to detect visually, so specialized equipment is required when leaks occur.

I guess we have all had the experience of trying to find a puncture in a bicycle tire by blowing up the tube and passing it through a bucket of water, looking for bubbles.

The principle is the same as finding a leak in gas piping with a solution of soapy liquid. The escaping gas causes bubbles to form, identifying the position of the leak. However, this method is lengthy and time-consuming, so modern leak detectors have stepped in to make the life of AC installers and technicians a little easier.

How refrigerant leak detectors work depends on the type of sensors they use to identify refrigerant gases. Refrigerant leak detectors detect natural gases like methane, but detectors that use the heated diode or infrared systems cannot pick up nitrogen gas traces because the atmosphere is seventy percent nitrogen.

How Do Electronic Refrigerant Leak Detectors Work?

Several different electronic leak detectors are commonly used in the air conditioning industry to detect leaks.

Infrared Sensors

These sensors use infrared light to pinpoint leaks in piping. The infrared beam illuminates the gas that escapes from the leak and confirms the leak’s location. Although the sensors on an infrared device are long-lasting, the unit does have the disadvantage that the sensor has to keep moving, which may be detrimental to accurately identifying the position of the leak.

Get the Green Building Project Checklist

Use this handy checklist on your next project to keep track of all the ways you can make your home more energy-efficient and sustainable.

Heated Diode

These detectors are highly accurate and detect the presence of gas by heating the refrigerant molecules and splitting them into chlorine or fluorine ions. Most modern refrigerants contain either chlorine or fluorine, with the latter being the most popular, so the heated diode can be used on almost all refrigerants. They can identify even small leaks; however, they do require careful maintenance and frequent cleaning. Usually the diode needs changing after a hundred hours of use.

Heated diodes will not detect refrigerants that contain hydrocarbons such as isobutane, propane or ammonia, which are commonly used in large refrigeration equipment. They are, however, highly sensitive to gases containing chlorine and provide quick responses.

Ultrasonic Detector

These units are sensitive to the sound the escaping gas creates and sometimes also combine sensitivity to the change in pressure near the leak. The sound of the escaping gas is not audible to human ears. However, ultrasonic detectors can pick up the sound and provide timely alerts to maintenance personnel or the air conditioning technician.

The disadvantages of this system are that not all leaks produce an ultrasonic sound, and it is not very effective in a noisy environment. Furthermore it is not accurate at pinpointing the position of the leak.

The system can be used to find leaks in any pressurized or vacuum gas system.

Corona Sensor Refrigerant Leak Detector

The detector draws air through an electrical field, and when a gas is present in that field, the change in the current sets off the alarm. The presence of gas causes the electrodes in the sensor to light up as the gas around the electrodes is ionized. The problem with these sensors is that they are not substance-specific, so any gas that finds its way into the field will trigger the alarm.

How to Use a Refrigerant Leak Detector

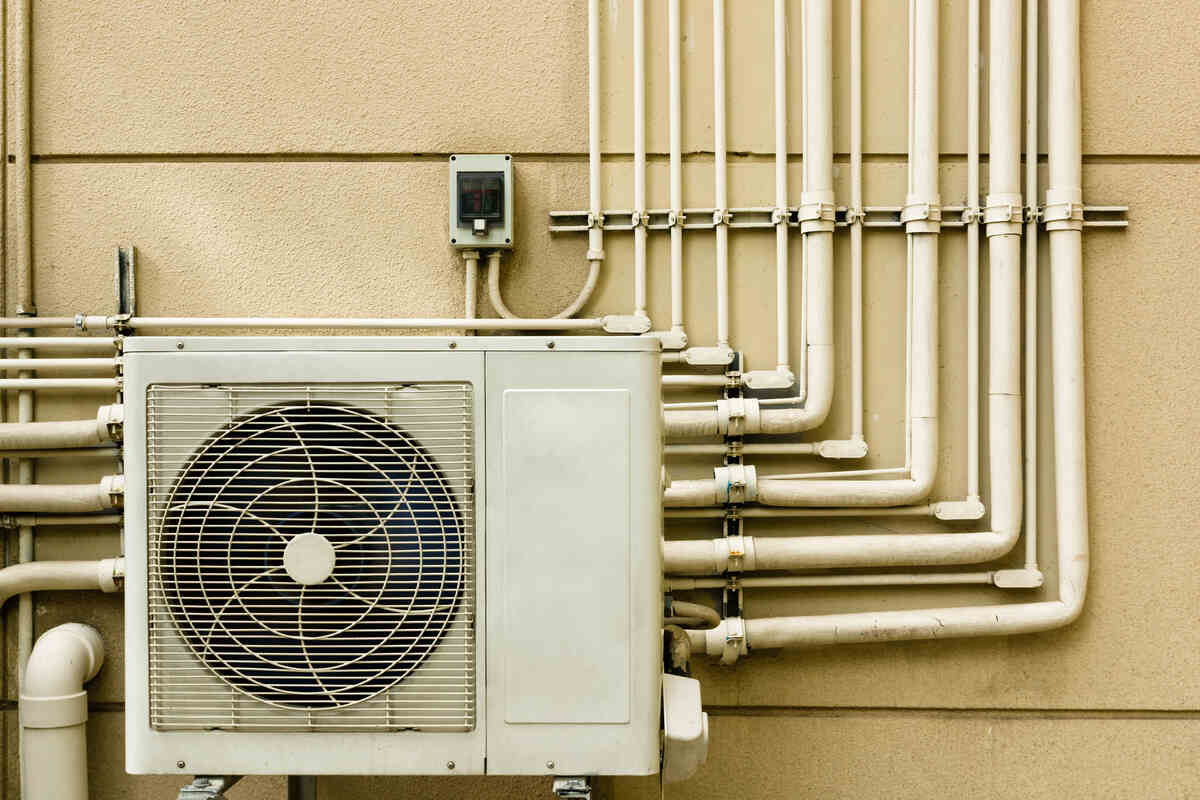

Finding the leak in a maze of piping can be disconcerting, but combining traditional and modern electronic detection devices should make the search a little easier.

Refrigerant gas is heavier than air, so starting your search at the unit’s base may provide some trustworthy clues about the leak’s position.

Spend some time visually checking the system. Look for oil traces or possible signs of leaks. Once you have reviewed the system, make sure that the detector you will use is correct for the type of refrigerant in the system.

Once the electronic detector is switched on, pass it slowly over the pipes, scanning back to try to identify the leak. Avoid aiming the detector at a constant position, as this could cause it to zero out. Rather, move the detector along the pipes and back in a sweeping motion.

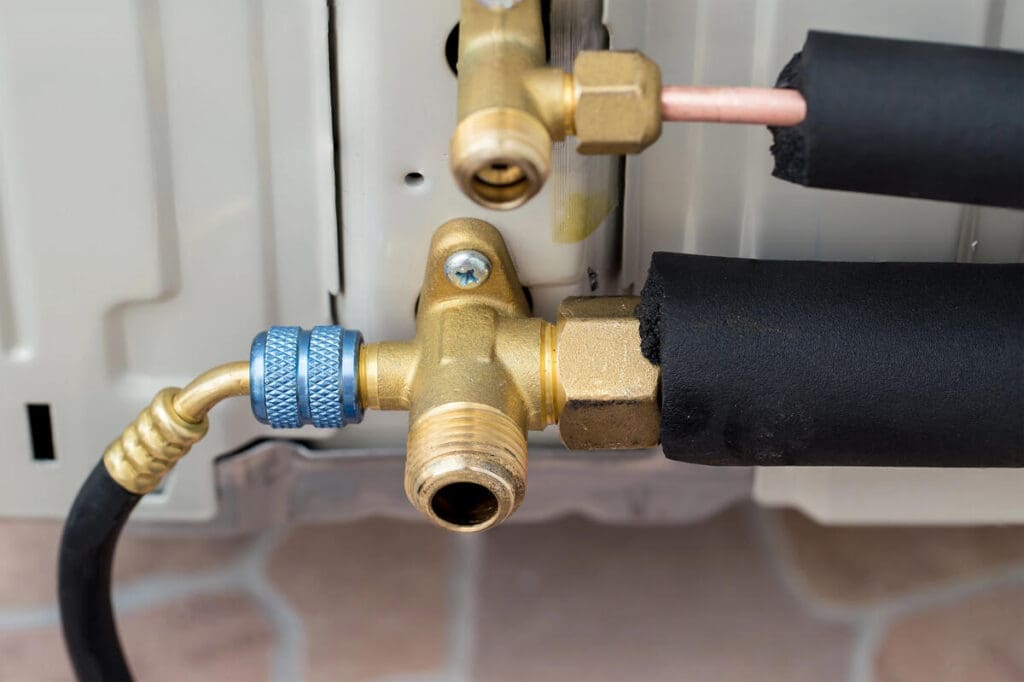

Once the electronic detector has identified the position of the leak, it would be a good idea to confirm the location by applying some leak detector fluid to the area and waiting for bubbles to form to fix the leak position accurately. While a normal soapy solution will do the job, a solution specifically manufactured for leak detection will provide more reliable results.

What Are the Best Refrigerant Leak Detectors?

The Inficon D-TEK Stratus refrigerant leak detector and portable monitor is known for its dual cloud hunting and pinpoint detection modes.

It can detect CFCs, HCFCs, HFCs and HFOs and has a sensitivity of 0.03 oz per year and a long-lasting sensor. In addition to refrigerants, with the optional sensors that are available you can easily switch modes to look for CO2 and flammable refrigerant leaks.

Offering easy-to-use and precise functionality, the Fieldpiece DR 82 infrared refrigerant leak detector is an excellent A2L refrigerant leak detector and can also operate as a DR82 infrared refrigerant leak detector.

It has a large backlit screen for easy monitoring and is sufficiently sensitive to trace leaks of .03 oz/ year.

The DR 82 is sensitive to most refrigerant gases and is designed for use in HVAC, commercial and domestic cooling systems.

The Elitech HVAC Refrigerant Leak Detector with heated diode sensor Halogen Freon Sniffer Air Conditioning Detection is one of the first models to incorporate a Thin-film Transistor (TFT) screen for clear and accurate readings and is highly rated as a 134a refrigerant leak detector.

The detector is easy to operate, with a press-button control to adjust sensitivity or mute the buzzer. The sensitivity is sophisticated enough to register leaks of 0.01oz/year. The heated diode sensor provides more accurate readings for all halogen gases.