How Prefabrication is Shaping Sustainable High-Rises in Canada

By Nick Haughton, Director of ESG at Sapphire Balconies

Published: June 11, 2025

Canada’s construction industry is rapidly evolving to meet the growing demand for sustainable building practices. With rising urbanization, a shift towards more climate-conscious construction is necessary to mitigate the environmental impact of our expanding cities. Prefabrication is playing an increasing role in construction while also emerging as a solution to address Canada’s housing shortages.

The prefabrication sector is growing, as factors such as labour shortages and rising material costs drive a shift away from traditional building methods. A recent study from Scius Advisory found that companies involved in Canada’s prefabrication sector employ over 184,000 workers and generate $88.9 billion in revenue annually.

As Canada’s construction sector – the third-highest carbon emitter – grapples with the environmental impact of embodied carbon, prefabrication offers a solution. Canada’s growing urban centres, particularly cities like Toronto, Vancouver and Calgary, are seeing increasing demand for high-rise developments, and prefabrication presents an opportunity to make these projects more sustainable. Energy efficiency and the environmental impact of construction materials are critical considerations for developers in Canada.

Prefabrication and High-rise Construction

High-rise buildings present unique challenges when it comes to sustainability, particularly due to their scale and the reduced range of materials able to be used for their construction. Prefabrication is especially well-suited to this building type, as it simplifies many logistical challenges associated with delivering and assembling large quantities of materials.

Get the Green Building Project Checklist

Use this handy checklist on your next project to keep track of all the ways you can make your home more energy-efficient and sustainable.

Consider balconies as a case in point. Balconies are not often thought about when improving facades, however, they can be an area where simple and easy fixes can make a significant impact. Prefabricated balcony systems can incorporate lightweight, durable materials such as aluminum, which can significantly reduce the loads on the structure, meaning sheerwalls, columns, slabs and piling can be designed with fewer materials, ultimately making the whole building much more sustainable. Prefabricated balconies are also easier to transport due to their reduced weight, which results in fewer deliveries, lower fuel usage and decreased emissions.

Additionally, prefabricated systems often come with built-in thermal breaks, ensuring that energy efficiency is prioritized alongside emissions reduction. Factory-built balconies are delivered preassembled and factory finished to a high-quality standard with minimal on-site finishing, reducing the complexity and energy use of traditional builds. For residential high-rises, where multiple levels and units require identical or modular construction, prefabrication offers scalability without unnecessary environmental costs.

How Prefabrication Offers Greater Sustainability

Prefabrication offers a wealth of sustainability benefits both during construction and after occupation, which are driving its adoption in Canada’s high-rise construction sector.

One of the biggest advantages of prefabrication is its potential to reduce embodied carbon, which refers to the greenhouse gas emissions generated upfront when the building is constructed, mainly embodied in the building’s materials. This includes emissions from raw material extraction, manufacturing, transportation and assembly. Unlike operational carbon, which is linked to a building’s energy use once it is occupied, embodied carbon is locked into the construction phase, making it a one-time but significant environmental cost.

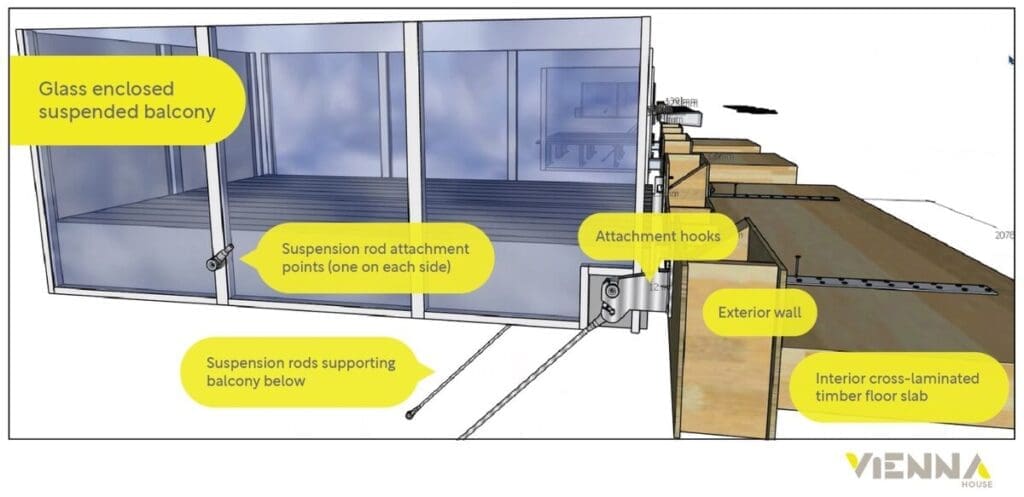

Another benefit is improved energy efficiency. Thermal bridging, which often undermines the energy efficiency of conventional structures, can be reduced by using innovative prefabricated solutions. For instance, Vancouver’s Vienna House project uses prefabricated balconies that attach to the building via clip-on brackets and suspension rods, so they transfer very little heat to the outdoors. Compared with the conventional approach to building, Vienna House’s balconies will allow just a fraction of heat to escape the building.

Additionally, with prefabrication, the utilization of materials can be tightly controlled in a factory environment, and all waste can be reused or easily recycled compared with site assembly. For instance, aluminum used in balcony systems or structural elements can be recycled at the end of a building’s life cycle. Prefabricated designs also make disassembly simpler, meaning components can be recovered and repurposed, limiting the need for unused raw materials in future projects.

Because prefabrication enables faster and cleaner construction, it can also reduce the ecological footprint of construction sites. By requiring fewer deliveries and generating less waste, prefabrication minimizes the impact on neighbouring ecosystems and urban environments.

Not only is there a lower environmental impact, but off-site manufacturing speeds up construction timelines, allowing buildings to be completed with fewer delays and less disruption to local communities. This shorter construction period helps recover lost time in projects that may have previously faced setbacks, such as issues with rebar and guard rail fixings. For instance, a developer of a high-rise housing project we’re working with in Hamilton, Ontario, says his construction team is shaving a full month off its timeline by using prefabricated balconies.

Challenges and Opportunities for Prefabrication in Canada

While the sustainability benefits of prefabrication are clear, its broader adoption in Canada is not without challenges. One hurdle is the initial investment required to establish prefabrication facilities and adopt new technologies. However, while there is a modest upfront cost premium, this cost is typically paid off over the long term via program gains, reduction of structural materials and reduced energy use.

There is also a regulatory aspect to consider. While cities like Toronto have made strides with standards such as the Toronto Green Standard, embodied carbon, in particular, remains largely unregulated. This presents both a challenge and an opportunity for the construction industry to lead with innovation. By adopting prefabrication and advocating for embodied carbon regulations, developers can position themselves at the forefront of sustainable construction.

Additionally, collaborations across supply chains are key to unlocking prefabrication’s full potential. The industry must prioritize partnerships with manufacturers, architects and sustainability experts to ensure that prefabricated components deliver the desired performance while meeting environmental goals.

The Path Forward

Prefabrication is undoubtedly shaping the future of construction in Canada, particularly in mid-to-high-rise developments where scalability and sustainability go hand in hand. By addressing critical issues such as embodied carbon, material efficiency and energy performance, prefabrication is enabling more climate-conscious buildings to rise in urban centres.

For developers, architects and other industry stakeholders, the opportunities presented by prefabrication are clear. Beyond simply meeting environmental targets, this building method offers operational efficiencies, long-term cost savings, and the ability to deliver high-quality structures with lasting impacts. By adopting prefabrication as a standard practice, Canada’s construction industry can take meaningful steps towards a more sustainable future.

Images from Sapphire Balconies

We are here to support the opportunities for Prefabrication in Canada. On June 5, Kalesnikoff Mass Timber formally opened the 100,000-sq.-ft. modular mass timber and wall panel prefabrication facility in Castlegar, B.C., to expand our mass timber products for use in multi-story housing structures, schools, daycares, commercial buildings, and other much-needed infrastructure.