It took about two thousand years to discover how the Romans and Greeks built seemingly indestructible, unreinforced cement structures that could magically repair themselves. A collaboration of scientists from Switzerland, Italy, and the U.S. recently discovered some fascinating elements of ancient concrete that offer exciting opportunities to produce low carbon concrete.

Concrete is responsible for approximately 8 percent of carbon emissions. Utilizing the ingenuity of our Mediterranean ancestors, we can make more durable low-carbon building materials and, quite possibly, carbon-neutral buildings. Here, we will investigate exciting environmentally friendly alternatives to traditional concrete.

Pozzolanic Cement

Conventional cement is made by crushing limestone and other materials like clay and shale and subsequently burning the material at temperatures around 1400°C (2550°F). In this way, lime is created by the process known as “calcination,” which accounts for 65 percent of CO2 emissions in cement manufacturing.

Introducing pozzolanic materials into cement manufacturing has a twofold advantage. Pozzolanic simply means materials that act in a similar way to cement. Its roots are in ancient Roman times when the material was sourced from the volcanic sites at Pozzuoli, near Naples.

These calcined clays can replace about 30 percent of conventional cement clinker. Their advantage is that they require a substantially lower manufacturing temperature, around 800°C (1470°F), which reduces the amount of process emissions and the heating requirements to complete the process.

Recycled Clinker – 60 Percent CO2 Reduction

Get the Green Building Project Checklist

Use this handy checklist on your next project to keep track of all the ways you can make your home more energy-efficient and sustainable.

The Holcim Group recently announced the results of its pilot project conducted at its Brookfield plant in Nova Scotia. The process of using recycled clinker was initially carried out in France in 2022. The impetus to encourage a circular economy where materials are recycled has gained significant support in the European Union, while the objective of the Canadian venture is to produce 100 percent recycled cement for its ready-mix operations.

The manufacture and use of recycled clinkers achieve several advantages, including a 60 percent reduction in CO2 levels.

Environmental Benefits of Using Recycled Clinker

- Avoids the use of finite materials

- Minimizes the amount of landfill waste

- Reduced manufacturing costs of recycled concrete

- Lighter concrete can be produced from recycled concrete

- Reduced greenhouse gas emissions

- Reduced water requirements

- Reduction in heat requirements to manufacture cement

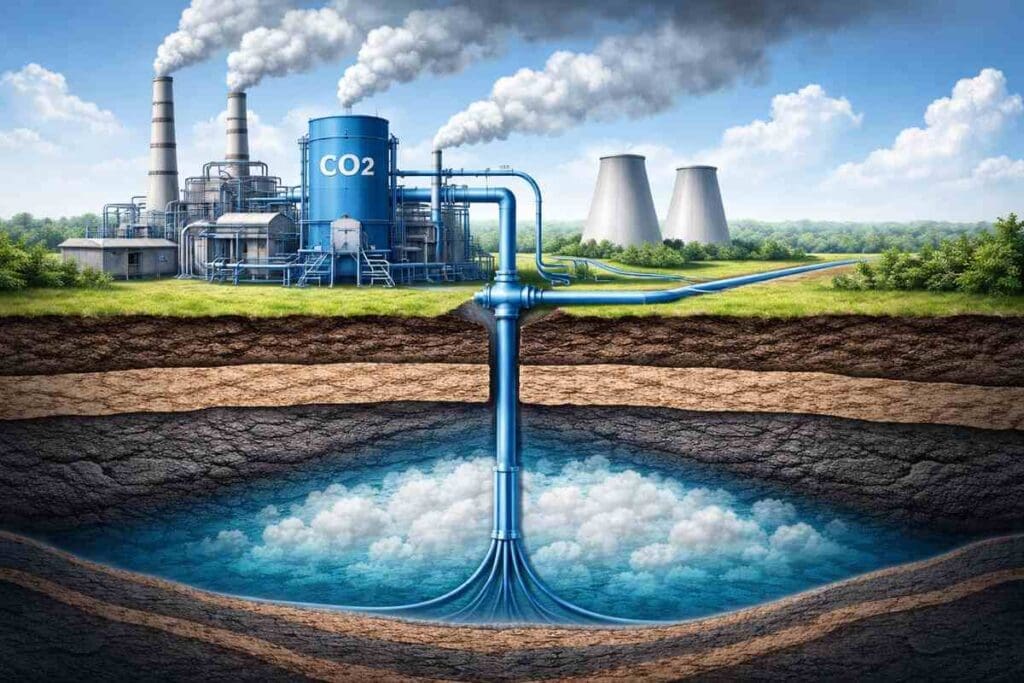

Carbon Capture

Introducing carbon dioxide into fresh cement is known as carbon capture. This process introduces CO2 into fresh concrete. Since concrete can absorb CO2, it can be stored in buildings in this way. The sequestration process converts the CO2 into a mineral that is permanently stored in the building’s structure. Tests on concrete that have been injected with CO2 indicate that the compressive strength of the sequestered concrete was superior to conventional concrete.

An alternative to this process is used to produce Sequestrated Carbon Cement (SCC), where CO2 is filtered through seawater. The resultant magnesium and calcium extracted from the seawater react with the CO2 to produce a top-quality white cement with superior strength qualities to conventional cement.

Low Carbon Cement Alternatives to Conventional Cement

Ekkomaxx Cement

The cement is made using 95 percent fly ash and 5 percent renewable liquid additives. The manufacturing process uses 50 percent less water and 95 percent less virgin material. The concrete produced shows superior durability and corrosion resistance to conventional concrete.

Geopolymer Cement

This type of cement has the advantage of replacing calcium oxide with far more benign aluminosilicates sourced from industrial waste materials like fly ash. The cement performs at similar levels to conventional cement but with a 95 percent reduction in carbon dioxide emissions.

Ferrocrete Cement

The glass and steel industries produce a waste product containing iron and silica, which is cured using a CO2 mixture that results in a cement with a carbon-negative rating.

Arqlite

As part of the innovations of Cemex Ventures, the Arqlite company produces gravel from recycled plastic. The product is a light artificial stone aggregate that has significant insulation and weight advantages over conventional aggregate.

The Measurement of Carbon Content

Two elements must be measured when valuing a building’s carbon emissions. Operational carbon measurement refers to the amount of carbon emitted from the building during its lifetime. It focuses on the energy requirements to maintain the building, such as heating, lighting and ventilation systems.

The other measurement is the carbon emissions involved in building construction. Embodied carbon relates to all the activities required to create the building, such as transporting and manufacturing building materials.

Both measures are used to calculate a building’s Life Cycle Assessment (LCA). Both elements need to be addressed to have a positive impact on reducing greenhouse gas emissions. To learn more about LCA, read our guide to ‘Life Cycle Assessment (LCA)‘.

Decoding the Jargon

The concrete and cement business has an almost limitless collection of abbreviations. To help you navigate the jargon, here is a list of the most commonly used ones.

LCA – Life Cycle Assessment

A building’s carbon emissions are valued starting from the sourcing of raw materials for the initial construction right through to the disposal of the waste materials following demolition.

LCM – Lightweight Concrete Materials

Materials such as vermiculite, perlite and expanded clay reduce the weight of concrete.

EPD – Environmental Product Declaration

Documentation such as ISO 14025 or EN 15804 standardizes a building’s or product’s environmental credentials.

MPA – Megapascal

The compressive strength of concrete is often measured as pounds per square inch, or the metric equivalent is 1 Megapascal = 145 pounds per square inch.

PCR – Product Category Rules

Rules that govern the assessment of a product.

GWP – Global Warming Potential

It is the estimated amount of CO2 emissions during the production of a building material.

PLC – Portland Limestone Cement

A reduced clinker content cement compared to Ordinary Portland Cement (OPC).

SCM – Supplementary Cementitious Material

Materials added to wet concrete to improve its properties.

RCA – Recycled Concrete Aggregate

This is also known as crushed concrete. Pre-used concrete that is broken up, impurities removed, and then crushed to comply with required specifications for reuse.

CDEW – Construction, Demolition, Excavation Waste

The waste is produced from demolished concrete and brick structures. It typically includes bricks, concrete, glass, metals and wood.

SDG – Sustainable Development Goals

United Nations’ goal for 2030 to create a planet of peace and prosperity with limited global warming.

CCUS – Carbon Capture, Utilization and Storage

The process of capturing emitted CO2 and storing it safely and permanently.

OPC – Ordinary Portland Cement

Conventional cement.

I learned this 7 years ago, when I heard of and bought the book, Drawdown, The Most Comprehensive Plan Ever Proposed to Reverse Global Warming, Edited by Paul Hawken. This wonderful book has a solution and photo for everything that could stop climate change. There are 100. Materials Alternative Cement is one of the them. We should all get the book.