Basements!!!

They are often dark, damp, and a flood risk. How can we mitigate?

In this weekly Q&A column, retired builder/building inspector Cam Allen answers readers’ home renovation questions. Have a question? Enter it in the form below.

Basements!!! They are often dark, damp, and a flood risk. How can we mitigate?

I have often been asked, why do we even have basements? The largest single reason: frost. If our homes are not based upon a solid frost-resistant foundation they will shift, crack, settle and move in wondrous ways, demanding repairs at often great expense. The other benefit from earlier times, the cold cellar was necessary for preserves and other food storage to get through the winter.

By experience, a wet basement is generally not the fault of the assembly or type, be it block, poured concrete or other methods. Most of the time it’s one or a collection of issues, the location, improper drainage above and/or below grade or the entire lot or neighbouring drainage. The first place to start in correcting a damp basement is getting your grades around the home, by way of gravity, flowing away from the structure. If the home lacks eavestrough, get it installed and direct your downspouts a minimum of 6 feet from the home or to your lot line.

If this drainage is present or correction has not made a difference, it’s either a lack of controlled drainage around the home at the base of the foundation or a water table issue. Up until the mid to late 70s the most popular way to install foundation drainage was clay tile located at the base of the footings. Over time these were notorious for filling up with silt and losing their ability to dissipate the water gathering around the base of the foundation by natural climate penetration of the soil or water table.

Today we use a high density polyethylene pipe called “Big O” that is a flexible, durable pipe with strategically located holes to allow the water to enter. It is now covered with a “sock” made of water permeable geotextile fabric that allows water in and keeps any silt and dirt out. This pipe is set in washed gravel along the side of the footing, not at the top of the footing as was common years ago.

This type of foundation drainage is now code for new homes in all provinces and most also require some manner of waterproof foundation coating like Blue-Skin or Yellowjack. One other method that is very common is called “dimpled foundation membrane.”

As this is a column on renovation answers, we are going to look at solutions for existing homes. While you can excavate around an existing home, this is not a cheap remedial step. It involves digging up around the entire home, moving existing landscape and decks, installing the foundation system and then re-landscaping. Estimates in the five figures are very common.

Get the Green Building Project Checklist

Use this handy checklist on your next project to keep track of all the ways you can make your home more energy-efficient and sustainable.

There is one alternative for older homes that is especially effective for a block basement. This installation would be an interior drain system. There are regional terms, French drain, interior perimeter drain system and sump systems are heard with French drain being the most commonly used term.

There are a number of pluses here, cost being the biggest factor. For an average-sized home I have never seen one quoted over $10,000 whereas an exterior retrofit commonly reaches well over double that figure. A French drain is nowhere near as disruptive and most reputable contractors offer a warranty – 10 to 20 years being common.

The floor-wall area must be clear for at least three feet around the entire basement. It’s best if the basement is empty. The contractor will cut the concrete pad around the basement, commonly about 18” wide away from the foundation. They then remove the concrete and any material, usually a thin layer of gravel and then soil to the depth needed for a channel with a good layer of washed stone brought in.

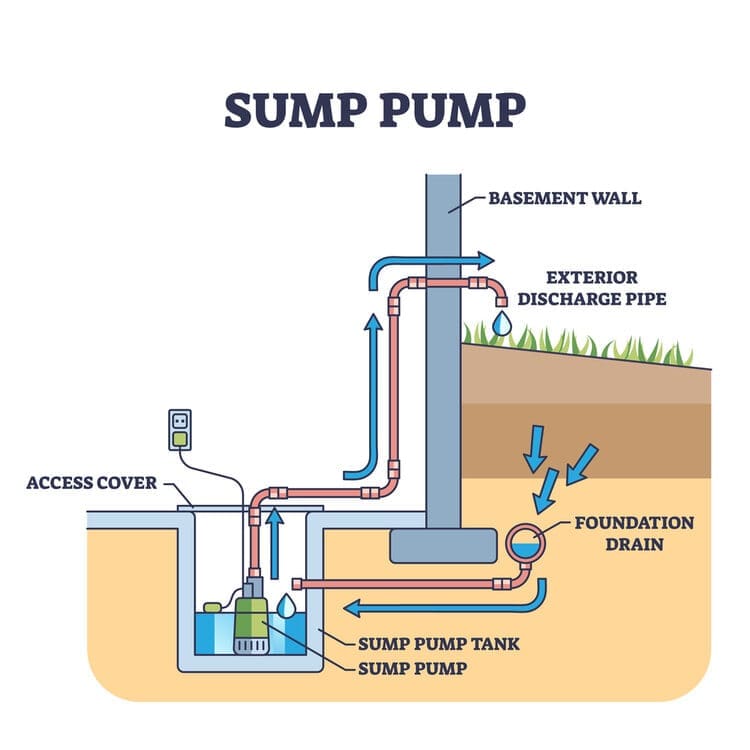

The same Big O pipe used on exterior below-grade drain systems is then set into the channel and wrapped around the washed stone. The trades I have used set the pipe with a laser for proper drainage slope to the sump pit. In one corner of the basement they will have added a sump pit liner and connected the Big ‘O’ pipe to this liner. It is set deeper than the channel and the liner rests upon similar washed stone.

They then install a sump pump and if done correctly, a backflow valve and a water level alarm. The discharge pipe is then extended out through the rim joint area and discharged at least 10 feet from the home or the lot line where a drainage swale between the properties is hopefully present.

The trades I have used for a block foundation, drill holes in the base row of blocks aiming for the space within the actual blocks. Then after ripping up strips of dimpled foundation membrane, they attach this membrane with Tapcon concrete screws and washers up on the block wall along the second course of blocks. They do this around the entire basement. They install this membrane with the dimples facing the wall so the weeping moisture drains down into the new drain channel. The last step is to replace the concrete and level to the existing basement pad. I have seen well over a hundred of these done and if properly installed this system works well.

There is one other interior drain system I have seen that also has a number of regional names, often called a baseboard drain system. There is no excavation done, the contractor fits sections of plastic track against the wall on the pad at the floor/wall joint. The plastic sections are sealed to the wall with epoxy. By experience, I have seen this done and in my opinion, the jury is out on their long-term practical use.

Images from Depositphotos

Have a Home Renovation Question?

Write it down below and we’ll get back to you. All questions get answered – every week, we’ll select one for publication in the column.