The history of modern fasteners dates back to the Bronze Age. In the ages since they’ve been perfected to provide an efficient and powerful way to join items together to create non-permanent joints. From the tiny machine screws that keep the cover on battery compartments of small electronic gadgets to the monstrously heavy bolts and nuts found in mining and marine applications.

Different materials require different types of fasteners. Basic fasteners like nails, tacks and staples have a wide range of applications – likewise screws, bolts and nuts have specific uses and provide a broad range of options as industrial fasteners. Rivets are a little more limited in their application, and then there are masonry and drywall screws.

So, which fastener has the right properties to ensure the materials you want to join stay together? Let’s find out.

The Different Types of Nails

For most of us, our first forays into woodworking involved common nails, sometimes hitting them well and at other times painfully missing them. Nails have different applications but share the common characteristics of having no thread and being driven into various materials by a percussion instrument, usually a hammer.

They usually feature a round head and shaft and are designed for a wide range of applications, from delicate finishing nails to more robust and larger types typically used in wood construction.

Here are some of the most common types and their use in different applications.

Get the Green Building Project Checklist

Use this handy checklist on your next project to keep track of all the ways you can make your home more energy-efficient and sustainable.

Box nails – The thinner shank of these nails makes them ideal for light construction on smaller wooden sections and prevents the wood from cracking.

Panel pins – Slimmer than box nails, they are designed for delicate woodworking projects. They are typically used to attach light mouldings, often in combination with wood glue.

Cut nails – Also called square nails, they have a long history and are used in heavier timber projects like flooring. The shank has a wedge shape with a blunt tip that encourages a firm anchorage in the timber. Unlike most other nails, which are drawn through a tungsten carbide die to create a regular shank, square nails are cut from a sheet of carbon steel. The additional strength of carbon steel makes these nails suitable for securing in masonry walls, as they resist bending.

Roofing nails – Designed to fix shingles or other roofing materials to the roof deck. They are short with broad heads and are typically coated with a corrosion-resistant material.

Slating nails – Similar in shape to roofing nails and are used to attach roof slates. They are normally 1.5 to 3 inches (38 to 75mm) long.

Siding nails – Sometimes called clout nails, they share the same wide heads as roofing nails but have longer shanks. They are used to attach siding and fibre-cement boards to structures.

Conical roofing nails – Used to attach roof tiles. The conical head is large enough to secure the roof tile, and they range from 1 to 3 inches long (25 to 75mm).

Concrete or masonry nails – Sometimes also referred to as hardened nails, they are designed to fix in concrete. Made of hardened steel with fluted shanks and sharp tips. They range in size from 1 to 4 inches (25 to 100mm).

Double-headed nails – These nails have two heads. They are typical examples of non-permanent fasteners, designed for easy removal and are ideal for temporarily fastening materials. They are used extensively in scaffolding and formwork, where structures are designed to be dismantled after use.

Nails for Use in Nail Guns

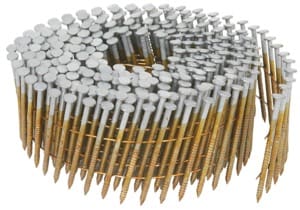

Typically used on building sites and wooden construction projects or wherever numerous nails must be inserted quickly, nail guns provide a quick and effortless means of nailing wooden sections together.

Nail guns use a variety of nails designed for specific uses. In most applications, the nails are arranged in a single straight layer. The roofing nail gun utilizes a canister or coil arrangement to facilitate the gun holding a greater number of nails.

Framing nails – Shoot nails up to 3.5 inches in length (90mm) and are used for applications using two-by-fours or two-by-sixes.

Siding nails – Similar to the nails of the framing nail gun, siding nails are a little shorter, ranging from 1.5 to 2.5 inches (35 to 65mm).

Finishing nails – Used to secure mouldings and other larger finishing pieces.

Brad nails – For smaller and more delicate work, these nails are used on light sections and thin panels. They have thin shanks and small heads, making them inconspicuous for delicate woodworking projects.

Roofing nails – Essential for roofing projects, roofing nail guns use short nails between 0.75 and 1.75 inches (20 and 45mm) long.

Cleats – Nails specially designed for use in laying hardwood floors. The ‘L’ or ‘T’ shaped head is typical of this type of nail, which ranges from 1.5 inches to 1.75 inches in length. (38mm to 45mm).

The Various Types of Wood Screws

Screws are essential construction fasteners and are made from different materials and incorporate various designs specifically for a wide range of materials.

Screws used in wood construction have a coarse thread over the bottom part of the shank and a wider head that accommodates the fitting in which the screwdriver is positioned to turn the screw into the wood.

The flat counter sunk screw with a slot to accommodate a flat screwdriver bit is the most traditional type of screwhead found in wood working projects. However, modern trends have seen other designs gain popularity.

Phillips screws – These screws have a four-pointed cross indentation that makes them suitable across a wide range of sizes.

Square drive – Also called Robertson screws, these screws have a square indentation that requires a square head driver of the correct size to drive the screw efficiently.

Hexagon-shaped – These screws with a hexagon-shaped indentation can be used together with an Allen wrench and offer the opportunity to apply greater torque to the screw.

Truss head screws – Have a large diameter head to distribute the load making them especially useful in soft materials.

Washer head screws – Incorporate a washer that also spreads the load especially useful in pocket hole construction methods.

Round head screws – Have a prominent head that provides additional strength while the lower profiled oval head has a less prominent profile.

Pan head screws – Used in instances where the appearance of screws in the finished product is acceptable.

Trim head screws – Less visible than pan or round head screws and are used where the appearance of the screw is not desired.

Drywall Screws

Designed to attach drywall panels to different substrates securely, drywall screws are divided into two types: S type for metal studs and W type for wood studs. Both are black in colour owing to the phosphate coating that protects them from corrosion.

Coarse-thread drywall screws – For attaching to wood, these screws are longer and thinner than those designed for attaching to metal studs. To provide a secure drywall panel, it is essential that a minimum of 0.6 inches (16mm) of thread is secured in the timber. Coarse threads are intended to attach drywall panels to softwood studs.

Fine-thread drywall screws – Have sharp points to penetrate steel studs and are generally shorter than their wood counterparts only requiring 0.38 inches (9.6mm) of thread to secure the drywall panel onto the steel stud.

Screws Made of Different Materials for Different Purposes

Industrial fasteners are made from different materials to withstand different climatic conditions. Stainless steel fasteners are used in the marine and other highly corrosive environments. They are made in various grades, with 316 stainless steel favoured for yachts and boating purposes.

Brass screws – A solid choice when used with polished brass fittings. They are resilient to woods with high acid content and can withstand outdoor conditions. However, care needs to be taken as they are limited in torque and prone to breaking if over-tightened.

Carbon steel screws – Sometimes referred to mild steel these fasteners are the most common and have many uses. In harsh conditions, they may be protected by non-corrosive coatings such as zinc. They are also the most cost-effective but may be susceptible to corrosion if used outdoors without a protective coating.

Masonry screws – Also referred to as concrete screws or cement screws, these screws have been specially hardened to cope with hard substances like concrete, brick and other cement products.

Types of Construction Bolts

Anchor bolts provide a strong connection between construction items and the concrete or brick structure. A hole needs to be drilled into the masonry material, the same diameter as the bolt. Once the bolt has been inserted into the hole and tightened, the external section of the anchor bolt located in the hole expands and secures the construction piece to the concrete. Anchor bolts provide a strong and permanent connection to the masonry section. They are often used to anchor heavy machinery and large or heavy steel sections.

Plow bolts – Used to fasten heavy equipment. They require predrilled holes with a countersink. The specially designed shape below the head of the bolt prevents it from rotating while being tightened.

Alloy steel bolts – Made with various alloys such as molybdenum, chrome or nickel. They are ideal for heavy-duty applications owing to the heat treatment they undergo, which results in a bolt with superior strength compared to a regular carbon steel bolt.

Solid rivets – Once a common fastener, their popularity has waned as bolts and nuts have replaced them as the most convenient fastener. In many instances, advances in welding techniques have made riveting construction methods obsolete.

Carriage bolts – Sometimes called coach bolts, they require correctly sized holes to be predrilled through the material before the bolt is inserted. Where the carriage bolt has a machined thread a washer and nut are used to secure the pieces together, however, where carriage bolts are used to join two pieces of wood together the bolt will have a coarse screw thread. The head will be shaped to allow the bolt to be screwed into the foundation piece. Carriage bolts are used together with large timber sections, producing a strong and resilient fastening.

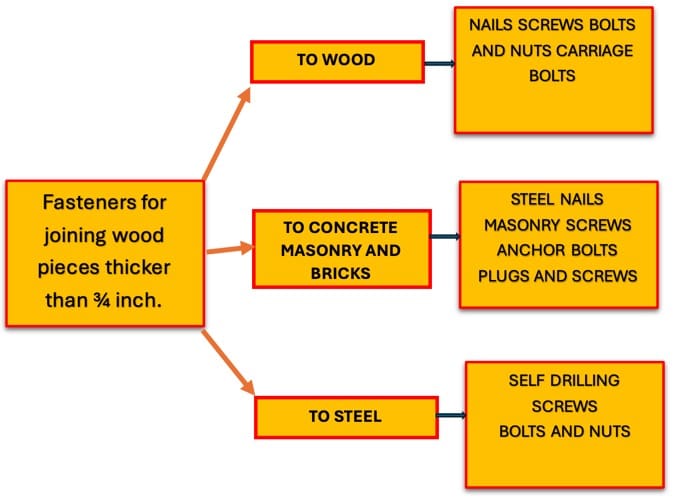

A Quick Guide to Fastener Selection