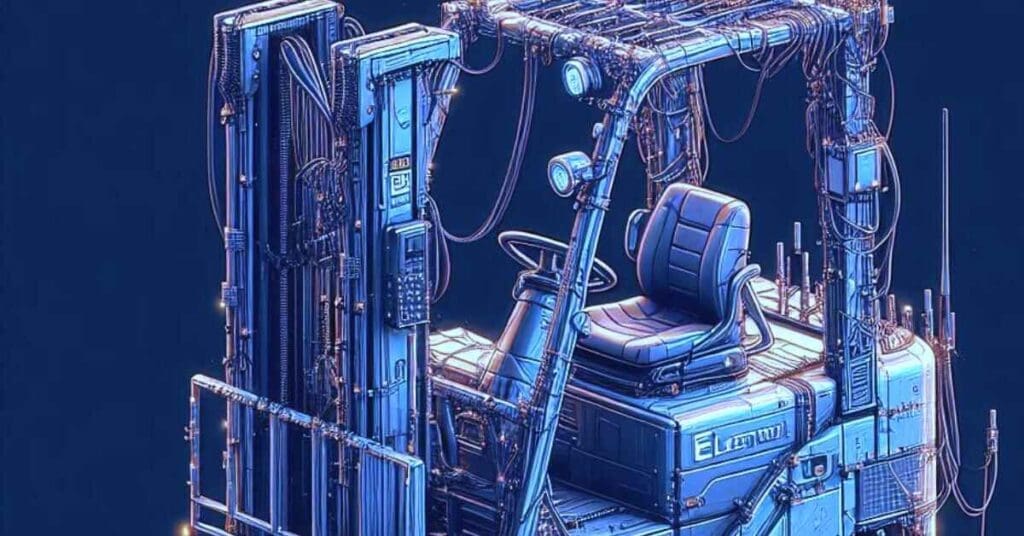

Elastochem, a visionary entity in the realm of building materials, has escalated its commitment to environmental stewardship by integrating electric forklifts into its daily operations. This strategic decision complements their ongoing environmental initiative, wherein the company repurposes over 200 million plastic bottles each year, utilizing them as a key component in the production of its Insulthane spray foam insulation.

The transition to electric forklifts represents a significant step forward in reducing the company’s carbon footprint. Unlike their diesel or gas/propane-fueled predecessors, electric forklifts are celebrated for their minimal environmental impact. They operate without emitting harmful pollutants, offering a clean alternative that contributes significantly to the reduction of greenhouse gases. By adopting electric forklifts, Elastochem is projected to prevent approximately 40 metric tons (equivalent to 36.3 tonnes) of CO2 emissions annually from contaminating the atmosphere. This not only underscores the company’s resolve in fostering a greener planet but also sets a benchmark for energy efficiency within the industry.

The benefits of electric forklifts extend beyond environmental conservation. These vehicles are notably quieter, thus reducing noise pollution and creating a more pleasant and productive working environment. Their energy efficiency is another hallmark; electric forklifts can operate for longer hours on a single charge compared to the fuel consumption rates of traditional forklifts, leading to lower operational costs and increased efficiency. Furthermore, the maintenance demands of electric forklifts are considerably lower, as they have fewer moving parts and do not require oil changes, fuel filters, or engine services. This reliability and reduced need for maintenance contribute to a decrease in the total cost of ownership over time.

Simultaneously, Elastochem’s innovative use of recycled plastic bottles in its Insulthane spray foam insulation exemplifies a robust response to the global challenge of plastic waste. By reprocessing these bottles into a valuable material, the company not only mitigates the environmental damage caused by plastic pollution but also promotes the use of recycled over virgin materials. This practice aligns with the principles of a circular economy, where products are designed and utilized in a manner that extends their lifecycle, thus conserving resources and minimizing waste.

The ecological benefits of utilizing recycled plastic bottles for spray foam insulation are manifold. It significantly diminishes the volume of waste destined for landfills, oceans, and other natural habitats, helping to preserve biodiversity and reduce the ecological footprint of human activities. Moreover, by substituting virgin materials with recycled plastic, Elastochem reduces the energy consumption and greenhouse gas emissions associated with the production of new plastic, further amplifying its contribution to environmental conservation.

Elastochem’s dual strategy of incorporating electric forklifts and recycling millions of plastic bottles into its product line is a testament to its unwavering dedication to sustainability. These initiatives not only exemplify the company’s commitment to combating climate change but also position Elastochem as a leader in sustainable business practices within the building materials sector. Through these actions, Elastochem not only contributes to a healthier planet but also sets a powerful example for others in the industry to follow, proving that environmental responsibility and business success can go hand in hand.