Installing a dryer vent hose in a cramped laundry room can be a challenge. Conventional hoses struggle to navigate tight corners or bends, often leading to kinking or collapsing. This can restrict airflow, potentially causing overheating issues or increasing the risk of lint buildup, posing fire hazards. Moreover, these limited spaces can make proper installation and maintenance a laborious task.

Some vent hoses can be too long or lack the flexibility needed to fit into these constrained areas, leaving homeowners at a loss. In this buyer’s guide we’ll look at our picks for the best dryer vent hose for small spaces, what makes a good hose so you know what’s right for you, as well as how to install them and know when to replace them.

What is a Dryer Vent Hose and What is Their Purpose?

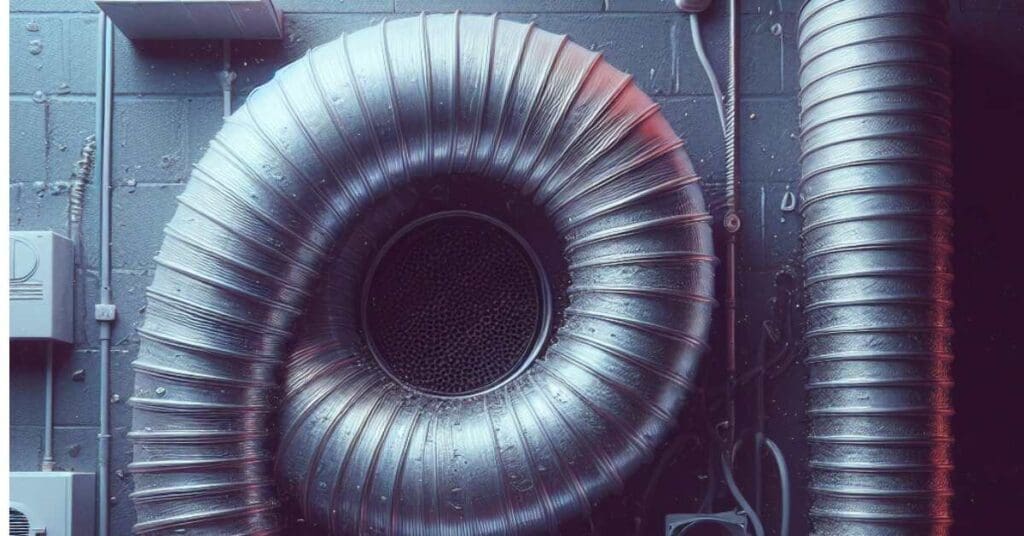

A dryer vent hose, also known as a dryer duct or transition duct, is a critical component of a clothes dryer’s ventilation system. Its primary function is to expel hot, moist air, along with lint and other particles, from the dryer to the outside of the house. This expulsion of air helps maintain proper airflow within the dryer, preventing overheating and potential fire hazards.

Typically made of flexible aluminum, foil, or semi-rigid materials, the hose connects the dryer exhaust port to a vent opening in the wall or through the roof. It’s crucial that the hose is properly installed to ensure efficient airflow and prevent blockages.

The standard diameter of a dryer vent hose is 4 inches, though other sizes are available for specific models or spaces. Hoses vary in length, often adjustable to accommodate different installation configurations.

An effectively functioning vent hose is essential for several reasons:

- Prevents the accumulation of lint in the dryer and surrounding areas, reducing the risk of potential fire hazards caused by lint buildup.

- Aids in maintaining the dryer’s safety and efficiency, as proper ventilation prevents overheating and potential fire hazards and allows for faster drying times and energy savings.

- Properly functioning vent hoses contribute to better indoor air quality. By expelling moist air outside, it helps prevent the buildup of excess humidity indoors, which can contribute to mould growth and other indoor air quality issues. Accumulation of moisture indoors can also lead to structural issues such as mould growth, deterioration of drywall, or damage to wooden structures.

Get the Green Building Project Checklist

Use this handy checklist on your next project to keep track of all the ways you can make your home more energy-efficient and sustainable.

How to Choose the Right Dryer Vent Hose for Tight Spaces

Before you choose any old dryer vent hose for a tight space, it’s important that you take all of the necessary purchasing considerations into account.

Space Constraints

When dealing with tight spaces, precision matters. Accurate measurements of the available space, including height, width, and depth, prevent issues like hose bending or crimping.

Vent Hose Types

Flexible aluminum – Renowned for its malleability, flexible aluminum hoses excel in tight spaces, easily conforming to the available room.

Slim ducts – Tailored for narrow areas, slim ducts offer a solution specifically designed to fit into confined spaces without compromising efficiency.

Material and Durability

Aluminum – Opting for aluminum ensures durability and resistance to corrosion, heat, and moisture. It’s a non-combustible material, enhancing safety.

Plastic – While plastic hoses are flexible and lightweight, they may be less durable and potentially flammable.

Fire Resistance

Prioritize hoses equipped with a fire-resistant coating or explicitly labeled as fire-resistant. This extra layer enhances safety, crucial in preventing potential fire hazards.

Length and Size

Select a hose with sufficient length to bridge the gap between the dryer and vent opening without unnecessary excess, which could lead to bends or kinks.

Flexibility and Bend Radius

A small bend radius and high flexibility are essential for a hose to navigate tight spaces without restricting airflow. This ensures efficient ventilation without compromising the hose’s structure.

Ease of Installation

Opt for hoses with user-friendly features like easy-to-use clamps or connectors. Simplified installation processes contribute to a hassle-free setup.

Airflow Efficiency

Maintaining optimal airflow is crucial to prevent lint buildup, ensuring the dryer operates efficiently. Choose a hose that facilitates consistent and unobstructed airflow.

Compatibility

Ensure the chosen hose aligns with your dryer’s vent opening specifications and the dimensions of the wall or floor vent. Compatibility is key for a seamless fit.

Insulation

Hoses with insulation layers are beneficial for spaces with varying temperatures. This feature prevents condensation and heat loss, contributing to efficient dryer operation.

Noise Reduction

Some hoses come equipped with features designed to reduce noise. This consideration is particularly relevant when the dryer is situated in living areas where noise can be a concern.

Warranty

A longer warranty period provides assurance of the hose’s durability. Opting for hoses with extended warranties can offer peace of mind regarding the product’s longevity.

Top Three Best Dryer Vent Hoses for Tight Spaces – Reviews

Let’s now take a look at the best dryer vent hoses that are ideal for small spaces.

Dundas Jafine BTD48TC Vents, 4-Inch

The Dundas Jafine dryer vent hose stands out as an optimal choice for compact spaces due to its construction and design features. Crafted from a robust four-ply aluminum foil laminate, this hose excels in durability and flexibility. This heavy-duty material not only ensures long-lasting performance but also provides fire resistance, adding a layer of safety to confined areas.

What sets this hose apart is its corrosion-resistant wire helix, granting it structural integrity while maintaining flexibility. This wire helix not only retains the hose’s shape but also facilitates effortless positioning and routing within a laundry space. Crucially, it aids in establishing an airtight seal between the dryer and the hose, a vital feature in compact setups.

UL listed and suitable for gas and electric dryers, this hose measures 8 feet in length with a 4-inch diameter. The inclusion of two clamps adds convenience, enabling secure connections between the hose, the dryer, and the vent exit. This hose’s compact size, coupled with its durable materials and secure seals, makes it an ideal choice for effectively managing limited spaces while ensuring efficient and safe venting for both gas and electric dryer units.

iPower GLDUCT4X8C Non-Insulated Flex Dryer Vent Hose

The iPower flexible dryer vent hose emerges as a cost-effective and efficient solution, particularly tailored for confined spaces, owing to its distinctive features and functionalities. Offering a 4-foot diameter and an 8-foot length, this hose adeptly caters to the venting requirements of various in-home dryers, making it an ideal fit for compact settings.

Included within this package are a pair of 4-inch metal clamps, simplifying the installation process, an invaluable feature especially in tight spaces where maneuverability is limited.

Notably, this dryer vent hose exhibits a thermal endurance range of 0 to 185 degrees Fahrenheit, ensuring suitability for various drying conditions. Constructed from flame-retardant aluminum material bolstered by a fireproof coating, it stands out for its safety-enhancing attributes, providing users with added peace of mind, a critical aspect in smaller spaces.

The incorporation of a corrosion-resistant wire helix further solidifies its stability and durability, promising enhanced performance and an extended lifespan. This comprehensive suite of features—ranging from its accommodating dimensions, safety provisions, to its reinforced structure—renders the iPower flexible dryer vent hose an exceptional choice specifically tailored to effectively serve within confined spaces while ensuring safety, durability, and optimal performance.

Builder’s Best 084718 All-Metal SAF-T Single Elbow

When it comes to accommodating tight spaces, Builder’s Best offers an optimal solution with its 8-foot transition duct, perfect for those seeking a semi-rigid dryer vent hose that combines efficiency and flexibility. Boasting a 4-inch diameter and a closed elbow enabling a 90-degree turn, this hose is engineered for enhanced maneuverability and adaptability, ideal for confined setups.

Beyond its practical dimensions, this product is UL listed, ensuring compliance with recommended dryer venting standards. The duct’s interior is crafted for a smoother airflow, significantly reducing lint buildup, thereby mitigating the risk of potential dryer fires—a crucial safety consideration in compact environments.

Moreover, this durable dryer vent hose exhibits exceptional resilience, capable of withstanding temperatures of up to 430 degrees Fahrenheit. This feature not only guarantees reliable performance but also ensures peace of mind, especially in spaces where safety is a top priority. Builder’s Best 8-foot transition duct emerges as an excellent choice for confined spaces, offering flexibility, safety adherence, and high-quality design to meet the stringent demands of compact laundry setups.

How to Know If a Dryer Vent Hose Needs to be Replaced

Regular inspection and cleaning of the dryer vent hose are crucial to ensure optimal performance and safety. This involves checking for any blockages, ensuring proper airflow, and cleaning out accumulated lint or debris. The following indicators aid in recognizing when a dryer vent hose needs replacement, promoting optimal dryer performance and reducing fire risks.

Age and Material

Consider the hose’s age and material. Over time, plastic hoses can deteriorate, while aluminum hoses might corrode or tear due to wear and tear. A general guideline is to replace hoses every 5 to 7 years.

Visible Damage

Inspect for visible signs of damage such as cracks, holes, or tears along the hose’s length. These compromises airflow and pose fire hazards, necessitating replacement.

Reduced Dryer Performance

If clothes take longer to dry or the dryer feels hotter than usual, it might indicate a clogged or obstructed vent hose, demanding replacement.

Excessive Lint Buildup

Examine the hose for excessive lint accumulation, restricting airflow. Lint buildup poses a significant fire risk and indicates poor ventilation, warranting replacement. It also reduces the dryer’s efficiency, forcing the dryer to work harder and consume more energy.

Poor Installation

Poorly installed or damaged vent hoses can pose serious risks. Blockages, kinks, or leaks in the hose can hinder airflow, causing overheating and potential fire hazards.

Condensation or Moisture

Moisture around the hose or within the vent itself could signify poor venting, causing condensation. Replace the hose to prevent mould growth and potential water damage.

Pests or Debris

Infestation by pests or debris within the hose obstructs airflow and poses hygiene and fire hazards. If present, consider replacing the hose.

Unusual Odours

Foul or burning smells while the dryer is running might indicate lint buildup or blockages within the hose, signaling the need for replacement.

Wear Around Connections

Check the connections at both ends of the hose for signs of wear or loose fittings. A secure and intact connection ensures proper venting.

Physical Restrictions

In tight spaces, kinks or folds in the hose can obstruct airflow. Opt for hoses designed for tight spaces to prevent this issue.

Regular Maintenance

Regular cleaning and maintenance of the dryer and vent system help in early detection of hose issues. Consider replacement if problems persist despite cleaning efforts.

Compliance with Safety Standards

Consider replacing hoses to adhere to updated safety standards or guidelines, especially when moving to a new residence or upgrading appliances.

Professional Assessment

When in doubt, seek professional inspection or consultation. A professional trained in dryer vent cleaning can assess the hose’s condition thoroughly.

How to Hook Up a Dryer Vent in a Tight Space

By following these steps diligently and ensuring a proper fit of the vent hose, you can effectively replace a dryer vent hose in a tight space while maintaining safety and efficiency in your laundry area. Here’s a step-by-step guide:

Tools and Materials Required

- Dryer vent kit (Ensure it’s suitable for tight spaces)

- Measuring tape

- Utility knife

- Screwdriver

- Pliers

- Vent hose

- Clamps

Step-by-Step Process

- Measure the space – Accurately measure the available space for the dryer vent, considering any obstructions like walls or cabinets. Choose a vent kit specifically designed for tight spaces.

- Prepare the dryer – Move the dryer to the desired location, allowing access to the vent opening.

- Identify the vent opening – Locate the vent opening on the back of the dryer. Use a utility knife to cut the opening if needed, ensuring a proper fit for the vent hose.

- Prepare the vent hose – Trim the vent hose to the appropriate length using a utility knife or scissors. Ensure it’s long enough to connect the dryer to the vent opening without excessive slack.

- Attach the vent hose – Connect one end of the vent hose to the dryer’s vent opening, securing it tightly. Use clamps or fasteners provided with the vent kit to ensure a snug fit.

- Position the dryer – Carefully slide the dryer back into place, taking care not to crimp or damage the vent hose. Ensure the hose doesn’t kink or bend excessively.

- Connect to the wall vent – Position the other end of the vent hose to the wall vent opening. Fasten it securely using appropriate clamps or fasteners.

- Secure and test – Double-check all connections to ensure they are secure and airtight. Turn on the dryer and run it for a few minutes to ensure proper airflow through the vent hose.

- Check for leaks or blockages – Inspect the entire vent hose to ensure there are no leaks, kinks, or blockages that could obstruct airflow.

- Final adjustments – Make any necessary adjustments to the hose or dryer positioning for optimal function. Ensure there’s no lint buildup around the connections.

- Safety check – Before regular use, conduct a safety check to ensure there are no overheating issues, unusual odours, or any other signs of malfunction.

- Regular maintenance – Schedule regular checks and cleanings of the dryer vent system to prevent lint buildup, which could lead to blockages or fire hazards.