C-Crete Technologies has developed the world’s first basalt-based concrete – it is cement-free and it is on par with conventional concrete in terms of cost and performance. Their product uses the non-carbonate rock basalt instead of Portland cement. Instead of the high heat and chemical processes required to make Portland cement, their process simply grinds the rock into cement powder, which they claim effectively eliminates the environmental concerns of production.

Though the construction industry has been moving towards more sustainable practices in recent years, one of the biggest issues still faced by builders is how to create durable and long-lasting structures without the use of Portland cement.

Since Portland cement is the world’s third largest source of anthropogenic carbon emissions, the material is a major focus of R&D as companies and research institutions try to develop ways to reduce its carbon footprint.

Companies like Holcim are now producing cement with 100 percent recycled clinker and CarbonCure injects captured CO2 into concrete to reduce its carbon footprint. There are others using supplementary cementitious materials (SCM) like fly ash and slag to replace a portion of Portland cement.

By substituting Portland cement for basalt, C-Crete’s concrete is a sustainable alternative on that basis alone. But they’ve also designed their product to capture carbon as well – so using it has the potential to reduce carbon emissions.

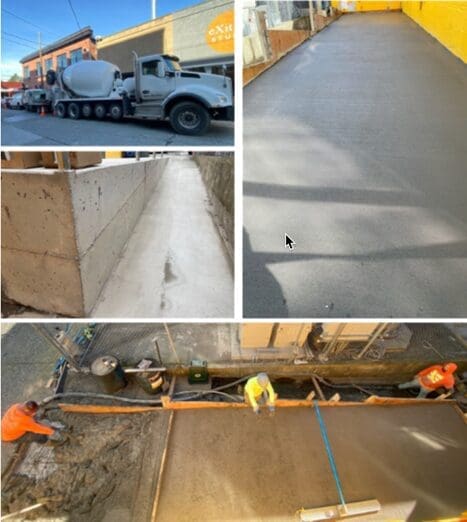

To this point, the company has already received over $3 million in funding from the U.S. Department of Energy to continue development and expand its operations. So far they have poured 140 tons of their basalt-based concrete to build Hubbard’s Corner, one of their flagship buildings.

According to C-Crete, “With the living laboratory of Hubbard’s Corner, this field trial moves C-Crete’s basalt-based C1157 concrete from a novel material to a pilot-ready concrete for bigger projects. This pour was that research and development step that proves an idea works, with validation from a real-world placement.”