Beyond Factory-Built

4 Alternatives to Manufactured and Modular Homes

In this weekly Q&A column, retired builder/building inspector Cam Allen answers readers’ home renovation questions. Have a question? Enter it in the form below.

For the past three weeks I have covered the history of factory-built homes,

different methods of construction and how to buy one. During this period I got a number of inquiries, surprisingly by a number of actual housing trades.

In most cases they offered an opinion and asked for mine so I felt this would

be a good wrap up on this subject. In my past I have built or been a subtrade on numerous kinds of alternative housing. Most of which were “on the edge” methodology ranging from straw bale to a dome kit home and a number with specialized custom frame or timber methods. Some of which I will admit that after we finished with the assembly, I made sure it was my first and last of this design!

Modular, factory-built, ready-to-move, assembled and manufactured homes – these names are all grouped together to refer to homes that are usually at least 80 percent finished and delivered to the site. They are then carefully placed on a prepared pad, crawl space or a full foundation.

This type of home is likely going to make up the largest percentage of new homes being built within the Build Canada Homes program. That said, there are some responsible alternatives that are not “out on the edge” of housing methods, rather options that can be considered if you are looking at a new home.

4 Alternatives to Factory-Built Homes

Get the Green Building Project Checklist

Use this handy checklist on your next project to keep track of all the ways you can make your home more energy-efficient and sustainable.

Panelized Construction

Probably the next most recognized assembly method after fully factory-built homes (like manufactured or modular) is panelized construction, often sold as prefab or SIP (Structural Insulated Panel) kit homes. These houses are essentially a jigsaw puzzle of wall, floor and roof sections manufactured in a factory and then trucked to the site for assembly.

I have been involved in building prefab and SIP homes and there are two major reasons to consider this system. It does reduce the build time considerably compared to a stick-built home and it allows the homebuyer full customization of the actual floor plan, something that factory-built homes usually have some limitations with.

Container Homes

The other method I have seen and been on site during an assembly is recycling shipping containers or “sea cans” as they are called.

Some years ago when CMHC was promoting the development of alternative methods with their EQilibrium Housing Program, I was invited to a showing by a container housing builder in Quebec. At the time CMHC was promoting building systems like modular, panelized and alternative housing methods.

I was pleased to see how they turned this eco-friendly, durable, versatile waterproof metal shell into an affordable home. Once inside you could not tell it was a sea can, except for the walls where the corrugated metal was left exposed. In one of the homes we saw, they had actually removed one of the side walls and welded two sea cans back together to arrive at a larger living area.

With today’s climate crisis I can see this type of housing method used in areas where a higher risk of forest fires is prevalent.

View our Container Homes Board on Pinterest to see a range of creative ways people are using shipping containers to build.

3D Printed Homes

Another method that is getting some press recently is 3D printed homes. While this may seem like something out of Star Wars it actually does have some strong possibilities.

There is a small community of builders who are promoting this housing system.

Using a very large 3D printer they can create the house structure layer by layer. Specially formulated concrete is layered to create the walls. I am aware of other materials like polymer but concrete seems to be the most common material.

The one advantage to this method is it allows for custom shapes, rounded walls and designs that are next to impossible to attain with conventional building methods.

There are some finished projects using 3D walls. One is a townhouse project in Gananoque, Ontario. If you are curious, go to the builder’s website. This project was approved by the town back in March of 2022 and they now have finished units.

Check out our 3D Printed Houses Board on Pinterest to browse through a bunch of unique designs.

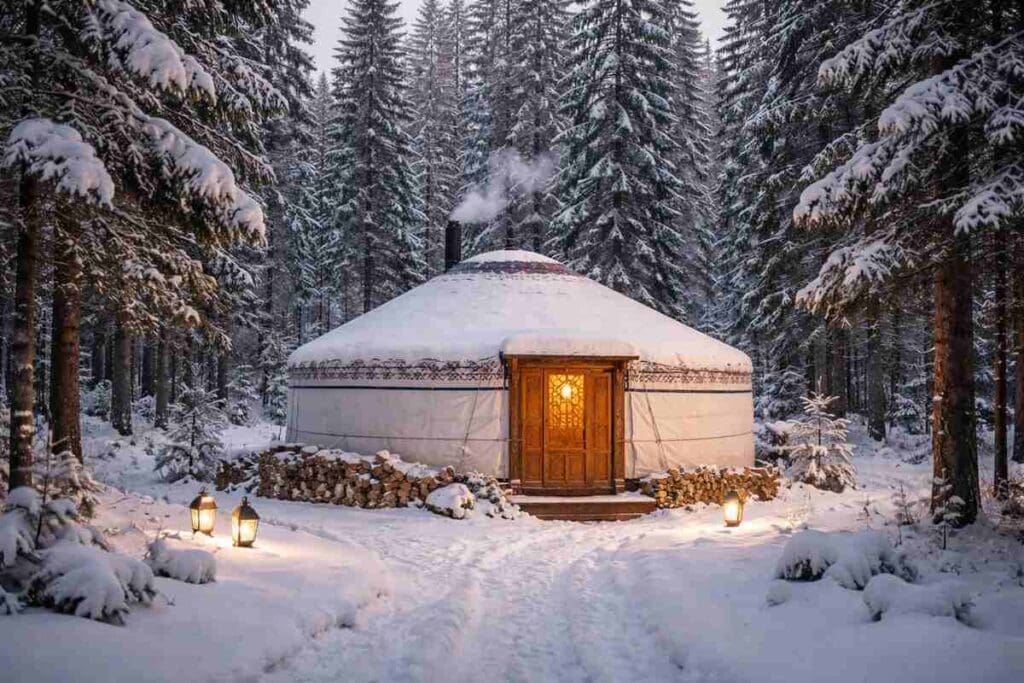

Yurts

The last housing system that I have seen is a unique, ancient form of housing called a “yurt”. Yurts are one of the oldest forms of portable housing, dating back thousands of years in Central Asia. Some years ago a local building official I knew, as his own residence, built two of these on a pad and joined them together with a short breezeway. The frame was metal and the walls spray

foamed to increase the overall structural integrity. Today, these round buildings are most often used for three-season cottages, guest residences and studios. I have always admired how the use of tension and compression of the frame provides for an open, comfortable living space.

I hope you have enjoyed this series on factory homes. I received a number of ideas from readers that could turn into a series as we strive to provide better, accessible and affordable housing.

Responses to Reader Questions

Use Existing Infrastructure vs New Build

Almost all of my trade inquiries on the 3-part series commented about using existing infrastructure. While new homes are needed, the municipal cost for services, roads, sewer and water and accessible land is a major cost consideration. Some municipalities began permitting “granny suites,” now considered an ADU (Accessory Dwelling Unit), in basements about 20 years ago. In 2019, Ontario, through its Planning Act, set the ground rules for ADUs.

These are smaller living spaces, often called driveway or tiny homes. They can

be built alongside a primary home on the same lot. Garages can be renovated to comply with ADU status, including adding a second residential level on a garage. Ontario allows for up to three additional dwelling units, separate from the primary residence. Quebec also permits ADUs in some areas.

Home Size vs Cost and Time

In today’s environment, cost of living and sustainability for a home with a footprint of 1,200 to 1,500 square feet gives ample space for 3 bedrooms, 2 bathrooms and a decent common space (kitchen-dining-living room) for a family of four.

Sadly, I still see dozens of what I call “Ego-homes” with footprints of 2,000 to 3,000 square feet being built today. Oftentimes with only one couple occupying the home. These homes are simply priced outside the budget for the majority of Canadians.

With the time it takes to build these huge homes, it’s tying up skilled trades that could build two or three sensible sized homes in the same time period. They are one of the major reasons we have a housing issue today.

Have a Home Renovation Question?

Write it down below and we’ll get back to you. All questions get answered – every week, we’ll select one for publication in the column.

Images from Depositphotos