Current Water Technologies Inc. (CWTI), a Canadian-based leader in sustainable water management, has unveiled its advanced ammonia treatment system, AmmEL-H2. The company, headquartered in Guelph, Ontario, specializes in electrochemical water treatment solutions designed to address critical issues like wastewater management and ammonia contamination.

AmmEL-H2 Ammonia Treatment Technology

The AmmEL-H2 system, developed in collaboration with the University of Illinois and the U.S. Army Corps of Engineers, is a groundbreaking solution that redefines how ammonia is managed in industrial and municipal water treatment systems.

Backed by $2.5 million in federal funding, the project highlights the global demand for innovative technologies that mitigate environmental harm while supporting economic growth.

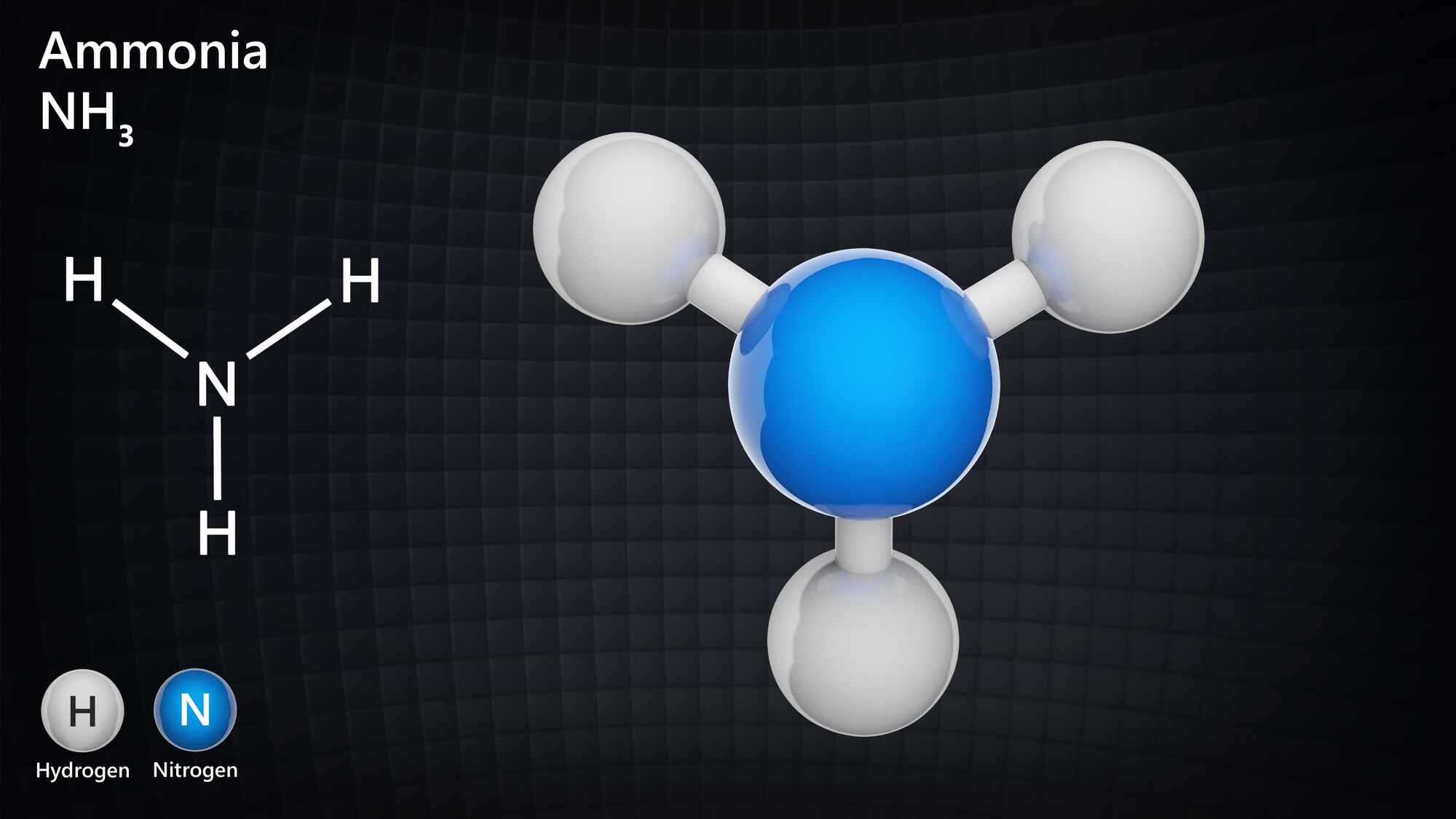

Unlike conventional biological treatment methods, which often produce greenhouse gases like nitrous oxide or carcinogens such as nitrate, AmmEL-H2 directly converts dissolved ammonia into environmentally benign nitrogen gas and creates hydrogen gas as a byproduct, which can be used as a sustainable energy source.

This electrochemical process is enabled by a proprietary self-cleaning reactor, ensuring efficiency and reliability, even in challenging northern climates where low temperatures typically pose problems to biological systems.

Addressing a Pressing Environmental Issue

Get the Green Building Project Checklist

Use this handy checklist on your next project to keep track of all the ways you can make your home more energy-efficient and sustainable.

Ammonia contamination is a critical concern for ecosystems, as it contributes to harmful algal blooms, disrupts aquatic habitats and compromises water quality.

Traditional treatment methods often face limitations, including temperature sensitivity and the production of secondary pollutants.

CWTI’s AmmEL-H2 system overcomes these challenges through a temperature-independent process, allowing for year-round operation in diverse environments.

It efficiently handles high concentrations of ammonia, making it ideal for applications in municipal wastewater plants, stormwater management, industrial effluent and even mine water treatment.

Environmental and Economic Benefits

The technology’s benefits extend beyond effective ammonia removal. The AmmEL-H2 system also generates high-purity hydrogen gas as a byproduct, providing a sustainable energy source that aligns with global initiatives to reduce reliance on fossil fuels.

This dual-functionality positions AmmEL-H2 as a transformative solution in both environmental management and renewable energy production.

Additional advantages include:

No harmful byproducts – Avoids the creation of nitrate and nitrous oxide, reducing carcinogenic and greenhouse gas outputs.

Low operational costs – The system features a smaller footprint, lower capital investment and reduced maintenance compared to traditional biological systems.

Rapid deployment – Its quick startup and shutdown capabilities offer flexibility for facilities adapting to fluctuating conditions.

Automated monitoring – Fully automated and remotely operated, it minimizes labour requirements and maximizes efficiency.

Potential Impact on Sustainability and Construction

The construction and infrastructure sectors stand to benefit significantly from AmmEL-H2. With increasing pressure to adopt sustainable practices, companies can integrate this technology to improve water quality, mitigate environmental risks and contribute to corporate sustainability goals.

Furthermore, by producing green hydrogen, the system supports a transition to cleaner energy sources, aligning with international climate targets.

Images from Depositphotos